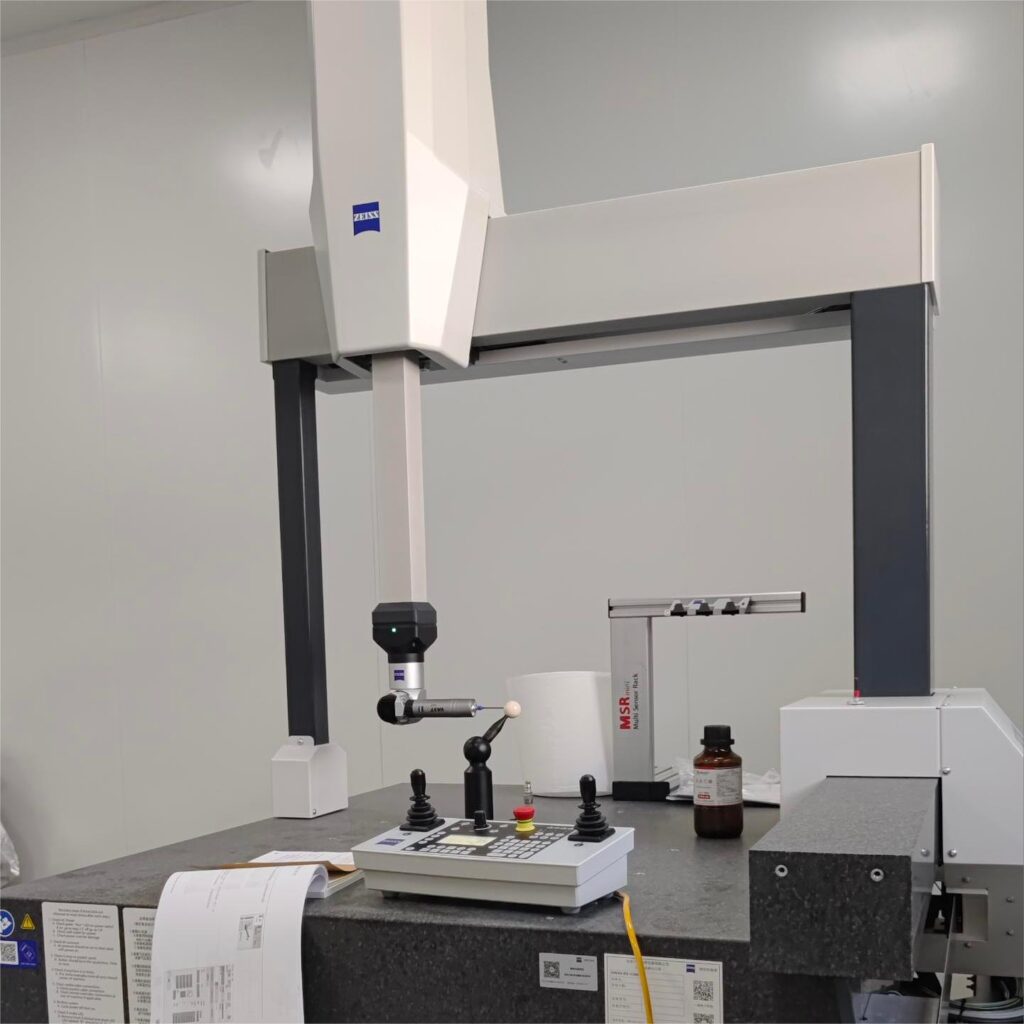

In today’s world of advanced manufacturing, precision isn’t optional—it’s expected. The Zeiss Spectrum CMM (Coordinate Measuring Machine) stands at the forefront of this expectation, delivering unparalleled accuracy in part inspection and dimensional verification. Used by top-tier manufacturers across the globe, the Zeiss Spectrum ensures that each component produced meets exact specifications

This sophisticated machine plays a critical role in modern CNC operations, where tolerances are tight and quality standards are non-negotiable. At Progressive Turnings, Inc., the Zeiss Spectrum supports our commitment to excellence by providing real-time validation that every part we produce meets or exceeds customer expectations.

Table of Contents

A Brief History of CMM Technology

Coordinate Measuring Machines first emerged in the 1950s as manual inspection devices that used touch probes to measure dimensions. By the 1970s, digital controls and computer integration allowed CMMs to evolve into programmable systems capable of automated, repeatable measurements.

Zeiss, a global leader in optical systems and metrology, introduced the Spectrum line to provide high-performance measurement with greater accessibility. The Spectrum series quickly gained recognition for delivering reliability, repeatability, and precision—critical qualities in an era where even microscopic deviations can impact product functionality or safety.

How the Zeiss Spectrum CMM Works

At its core, the Zeiss Spectrum operates by using a high-precision probe that moves across X, Y, and Z axes to record spatial coordinates of a part. These points are used to generate a three-dimensional map of the object being inspected, which is then compared to the original CAD design.

This process allows for accurate analysis of complex geometries, surface profiles, and dimensional tolerances. By integrating advanced sensors, software, and automation, the Spectrum minimizes human error while delivering highly repeatable measurements—perfect for quality control in high-volume production environments.

4. The Importance of Traceability and Documentation

In industries like aerospace, automotive, and medical devices, documentation and traceability are essential. The Zeiss Spectrum CMM offers detailed reports and data logs that ensure each measurement can be traced back to specific parts and manufacturing runs.

This not only supports compliance with ISO standards but also adds another layer of confidence for our clients. At Progressive Turnings, we integrate CMM data into our broader quality management systems, allowing us to track performance trends, identify issues early, and continuously improve our manufacturing process.

Enhanced Software Integration for Smarter Results

The power of the Zeiss Spectrum goes beyond its hardware. It is paired with Zeiss CALYPSO software, which enables intuitive programming, graphical reporting, and complex inspection routines with minimal operator training. This software bridges the gap between design and production by comparing live measurements to digital CAD files.

Automated routines and customized reporting streamline the inspection process and reduce turnaround time for quality assurance. As a result, issues are identified faster, rework is minimized, and client satisfaction is increased. In short, smart software makes smart manufacturing possible.

Flexibility Across Multiple Part Types

Unlike traditional measuring tools that may only suit specific part shapes or sizes, the Zeiss Spectrum CMM can handle a wide variety of components—from small, intricate medical parts to larger structural pieces used in transportation and automation.

This adaptability makes it ideal for a job shop like Progressive Turnings, where we serve multiple industries and encounter different tolerance requirements. With modular fixturing and variable probe systems, the Spectrum adjusts to unique part geometries, ensuring accurate inspections no matter the project.

Training and Skill Development

Operating a Zeiss Spectrum CMM requires precision not just from the machine but from its human operators. At Progressive Turnings, our team undergoes specialized training to ensure we utilize the full capabilities of the CMM system. This includes coursework in metrology principles, CAD interpretation, and CALYPSO software proficiency.

Investing in training ensures our operators can create custom programs, troubleshoot inspection plans, and contribute directly to our quality assurance workflows. The result is a team that’s empowered, knowledgeable, and aligned with our mission of delivering unmatched precision.

Real-World Applications in CNC Machining

Every CNC part we machine is only as good as our ability to verify its precision. The Zeiss Spectrum plays a vital role in validating dimensions, particularly for tight-tolerance components used in aerospace brackets, medical fixtures, and high-speed automation parts.

Whether verifying hole positions, flatness, concentricity, or thread profiles, the CMM confirms that specifications are met. This minimizes waste, prevents client rejections, and improves operational efficiency. For our customers, that means fewer headaches and consistently high-quality results delivered on time.

Staying Ahead in a Competitive Industry

Manufacturing is evolving rapidly, and staying competitive means adopting tools that improve accuracy and efficiency. By integrating the Zeiss Spectrum CMM into our workflow, Progressive Turnings positions itself ahead of the curve.

We can guarantee not only that a part is dimensionally accurate but that it’s backed by verifiable data. This allows us to win trust with clients in demanding industries, meet ISO 9001:2015 requirements, and retain long-term partnerships with OEMs and tier-1 suppliers alike.

The Progressive Turnings Standard

At Progressive Turnings, Inc., quality is never an afterthought—it’s our foundation. The Zeiss Spectrum CMM plays an essential role in helping us uphold this standard. From first article inspection to in-process checks and final validation, it ensures we deliver parts that meet exact specifications with confidence.

Our investment in world-class metrology equipment like the Zeiss Spectrum reflects our dedication to precision, customer satisfaction, and continuous improvement. Because for us, it’s not just about machining parts—it’s about measuring up to the highest expectations in the industry.