One and Done

Precision in a Single Operation

Maximizing Efficiency, Reducing Handling, Delivering Quality

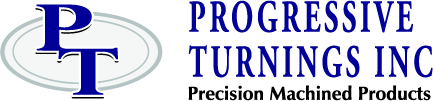

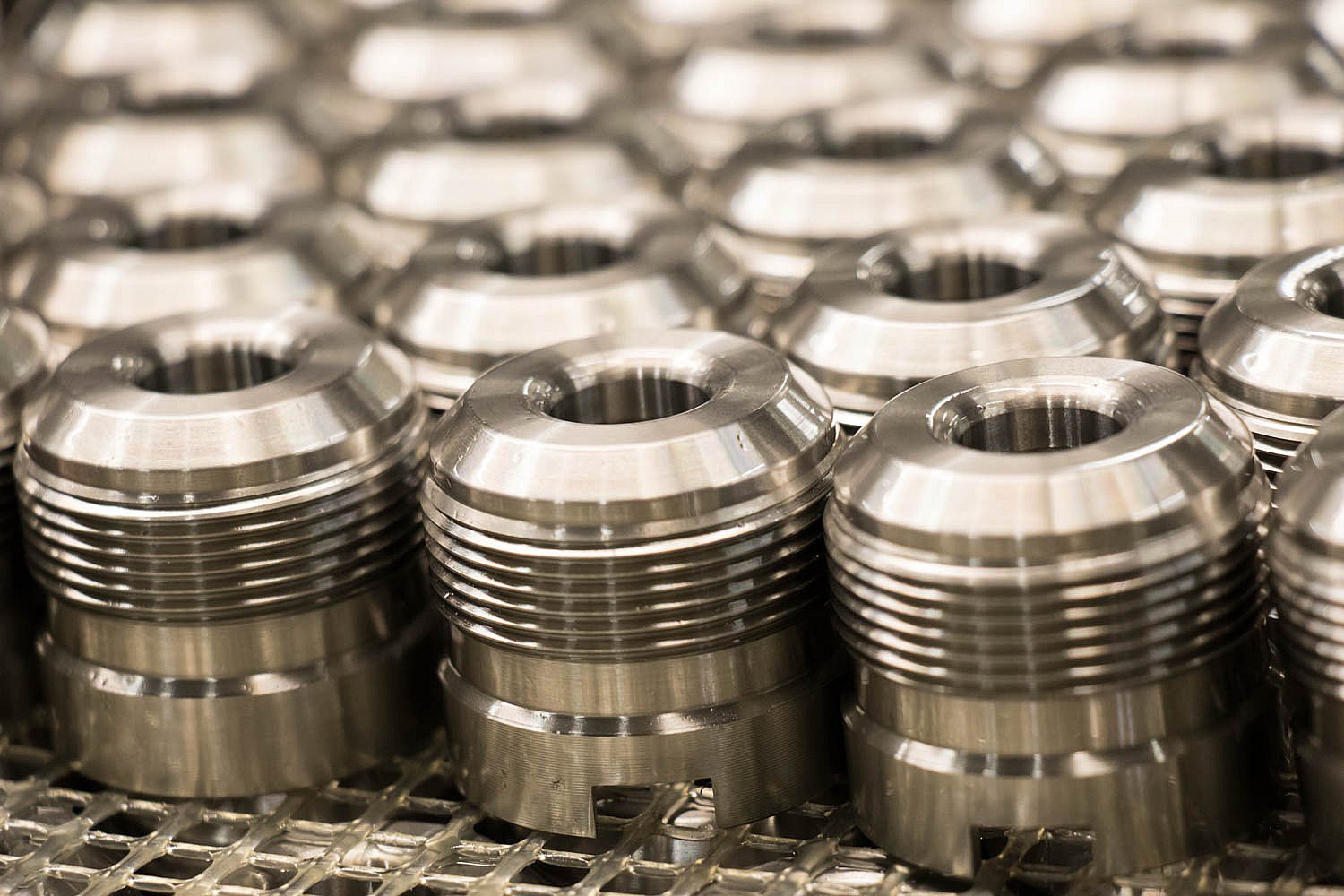

At Progressive Turnings, we believe in working smarter and more efficiently. That’s why we embrace a production method we call “One and Done”—completing complex parts in a single operation. This approach minimizes handling, reduces lead times, and enhances overall part quality.

Our advanced CNC turning centers are equipped with live tooling and sub-spindles, enabling multiple machining processes—like milling, drilling, broaching, and splining—to be completed within a single setup. Parts are seamlessly transferred between spindles, allowing for complete machining on all sides without additional setups.

With up to 8 axes of simultaneous motion, our machines are capable of performing turning and milling operations at the same time, dramatically cutting cycle times and boosting productivity.

We continually reinvest in cutting-edge equipment and tooling to stay at the forefront of technology, empowering our skilled team to deliver faster, more accurate, and more visually refined parts than ever before.

Progressive Turnings has the equipment and expertise to meet your most demanding machining requirements—efficiently and precisely.